Electrical Equipment Maintenance

In our work, we often encounter customers asking daily maintenance problems of electrical equipment.

Today, Jiangxi Yikai Electric will introduce you to the basic principles of electrical equipment maintenance, all of which are summaries of actual work.

Every electrical worker must study carefully and earnestly understand that they will definitely play a role in actual work!

1. Start speaking first

For the faulty electrical equipment, do not be in a hurry, you should first ask about the process before and after the fault and the fault phenomenon.

For rusty equipment, you should also be familiar with circuit principles and structural characteristics, and observe the corresponding rules.

Before disassembling, you must be fully familiar with the function, position, connection method and relationship with other devices around.

If there is no assembly drawing, you should disassemble, draw a sketch, and mark.

2. Outside first

You should first check the equipment for obvious cracks and defects, understand its maintenance history, service life, etc..

and then check the inside of the machine.

Before disassembling, the surrounding fault factors should be queued, and it can only be disassembled after it is determined as an internal failure.

Otherwise, blind disassembly may damage the equipment over time.

3. Mechanical first, then electrical

Only after confirming that the mechanical parts are fault-free, then conduct electrical inspections.

When checking circuit faults, you should use the testing equipment to find the fault location, confirm that there is no bad contact fault, and then check the operation relationship between the circuit and the machine in order to avoid misjudgment.

4. Static first, then dynamic

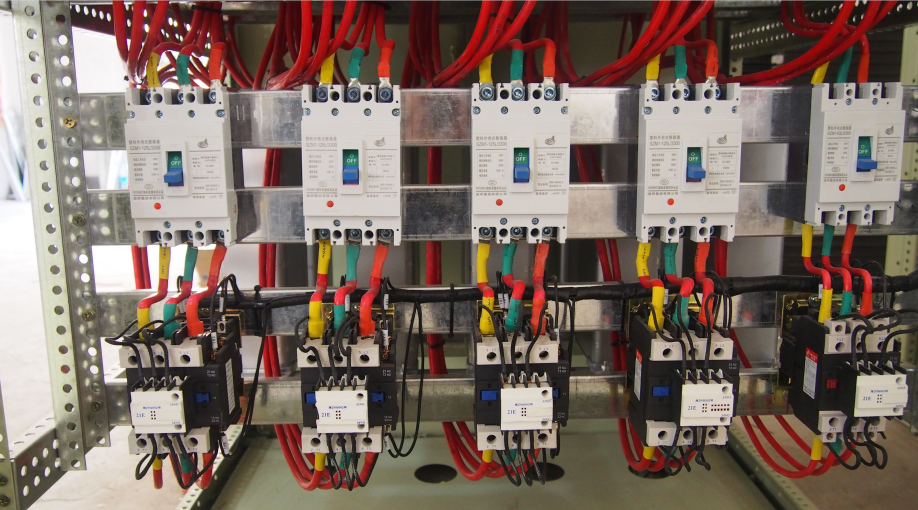

When the equipment is not energized, determine whether the electrical equipment buttons, contactors, thermal relays and fuses are good or bad, so as to determine the fault.

Power on test, listen to its sound, measure parameters, determine faults, and finally carry out maintenance.

If the phase of the motor is missing, the three-phase voltage value cannot be discriminated, you should listen to its sound and measure each relative ground voltage separately to determine which phase is missing.

5. Clean first ,and then repair

For heavily polluted electrical equipment, first clean the buttons, wiring points, and contact points,

and check whether the external control keys are malfunctioning.

Many faults are caused by dirt and conductive dust.

Once the fault is cleaned, it is often eliminated.

6. Power first, then device

The failure rate of the power supply portion accounts for a high proportion of the entire faulty equipment, so it is often more effective to repair the power supply first.

7. Universal before extraordinary

Failures caused by the quality of assembly parts or other equipment failures generally account for about 50% of common failures.

The extraordinary faults of electrical equipment are mostly soft faults, which require * experience and instrumentation to measure and maintain.

8. Peripheral first

Don’t rush to replace damaged electrical components first, and then consider replacing damaged electrical components after confirming that the peripheral circuit is normal.

9. DC before AC

When overhauling, the static working point of the DC circuit must be checked first, and then the dynamic working point of the AC circuit.

10. Debug after failure

For the electrical equipment with debugging and fault coexisting, the fault should be eliminated first and then debugged.

The debugging must be carried out under the premise of the electrical line speed.

Inspection methods and operating practices

1. Intuitive method

Intuitive method is based on the external manifestation of electrical faults, through watching, smelling, listening and other means to check and determine faults.

(1) Inspection steps:

Investigation situation:

Inquire the operator and the personnel present at the fault, including the external appearance of the fault, the general location, and the environmental conditions at the time of the fault. If there is no abnormal gas, open flame, whether the heat source is close to the electrical appliance, whether there is corrosive gas intrusion, whether there is water leakage, whether someone has repaired it, the repair content, etc. Preliminary inspection: According to the investigation, see if there is any damage to the exterior of the electrical appliance, whether the connection is broken, loose, whether the insulation is scorched, whether the fuse indicator of the spiral fuse jumps out, whether the electrical appliance has water ingress, grease, switch position Is it correct to wait.

Test run:

After preliminary inspection, after confirming that there will be further expansion of the fault and cause personal and equipment accidents, you can further test run inspection, pay attention to whether there are serious flashovers, abnormal odors, abnormal sounds and other phenomena in the test run, and should stop immediately once found. cut the power supply. Pay attention to check whether the temperature rise of the electrical appliances and the action procedures of the electrical appliances meet the requirements of the schematic diagram of the electrical equipment, so as to find the faulty parts.

(2) Inspection method:

Observe the sparks:

When the contacts of the electrical appliance are closed, the circuit is broken or the wire end is loose, a spark will be generated, so you can check the electrical appliance failure according to the presence and size of the spark. For example, when a spark is found between a normally fastened wire and a screw, it means that the thread is loose or the contact is poor. When the contact of the electrical appliance closes or breaks the circuit, a flashover indicates that the circuit is on, and a non-flashover indicates that the circuit is off.

When the main contact of the contactor controlling the motor has sparks in two phases and one phase has no sparks, it indicates that the non-sparking one-phase contact is poorly connected or the circuit of this phase is open; the sparks of two phases in the three phases are larger than normal, and the other phase If it is smaller than normal, it can be preliminarily determined that the motor is short-circuited or grounded; the three-phase sparks are larger than normal, and the motor may be overloaded or the mechanical part is stuck. In the auxiliary circuit, after the contactor coil circuit is energized, the armature does not attract. It is necessary to distinguish whether the circuit is broken or the mechanical part of the contactor is caused. You can press the start button once. If there is a slight spark when the normally open contact of the button is closed, it means that the circuit is in the fault. The fault is in the mechanical part of the contactor. If there is no spark between the contacts, it means that the circuit is open.

Action procedures:

The action procedures of electrical appliances should meet the requirements of electrical instructions and drawings. If an electrical appliance on a circuit moves too early, too late, or does not operate, it means that the circuit or electrical appliance is faulty. In addition, faults can also be determined based on the analysis of the sound, temperature, pressure, odor, etc. emitted by the appliance. Using intuitive methods, not only can determine simple faults, but also narrow down more complex faults to a smaller scope.

2. Measuring voltage method

The voltage measurement method is to measure the voltage value and current value of each point according to the power supply mode of the electrical appliance and compare it with the normal value.

It can be divided into hierarchical measurement method, segmented measurement method and spot measurement method.

3. Resistance measuring method

Can be divided into step measurement method and section measurement method.

These two methods are suitable for electrical equipment with large distances between switches and appliances.

4. Comparison, replacement of components, and gradually open circuit (or access) method

(1) Comparison method:

Compare the test data with the drawings and normal parameters normally recorded to determine the fault.

For electrical appliances with no data and no usual records, it can be compared with intact electrical appliances of the same model.

When the electrical components in the circuit are of the same control nature or multiple components jointly control the same device, other similar or same power supply components can be used to determine the fault.

(2) Set conversion element method:

The cause of the failure of some circuits is not easy to determine or when the inspection time is too long, but in order to ensure the utilization rate of electrical equipment.

It is possible to switch the component experiment with good performance of the same phase to confirm whether the failure is caused by this appliance. When using the conversion element method, it should be noted that after removing the original electrical appliance, it should be carefully checked whether it has been damaged.

Only when it is definitely due to the damage of the electrical appliance itself, the new electrical appliance can be replaced to prevent the new replacement component from being damaged again.

(3) Step by step open circuit (or access) method:

When multiple branches are connected in parallel and the circuit with more complicated control is short-circuited or grounded, it generally has obvious external performance, such as smoke and sparks. When the circuit inside the motor or the shielded circuit is short-circuited or grounded, it is not easy to find other external phenomena except the fuse blown. This situation can be checked by the stepwise open circuit (or access) method.

Step-by-step open circuit method:

When encountering a short circuit or ground fault that is difficult to check, the melt can be replaced again, and the multi-branch cross-link circuit can be disconnected from the circuit step by step or in a key way, and then energized to test. The fault is on the circuit that was just disconnected. Then divide this branch into several sections, and connect to the circuit section by section. When a certain section of circuit is connected, the fuse blows again, and the fault is on this section of the circuit and an electrical component. This method is simple, but easily burns electrical components that are not seriously damaged.

Step-by-step connection method:

When the circuit has a short circuit or ground fault, replace it with a new fuse and connect the branches one by one to the power supply step by step or focus, and try again. When a certain section is received, the fuse blows again, and the fault is on the circuit just connected and the electrical components it contains.

5. Forced closure

When queuing electrical appliances to fail, after visual inspection, no fault point is found and no appropriate instrument is available for measurement.

An insulating rod can be used to force the relevant relays, contactors, electromagnets, etc., to force the normally open contact Close, and then observe various phenomena in the electrical or mechanical parts, such as the motor never turns to rotate, and the corresponding part of the device never moves to normal operation.

6. Short circuit

The failures of equipment circuits or electrical appliances can be roughly classified into six categories: short circuit, overload, open circuit, grounding, wiring error, electrical and mechanical part failure of electrical appliances.

Among the various types of faults, more are open circuit faults. It includes wire disconnection, virtual connection, looseness, poor contact, virtual welding, false welding, fuse fusing, etc.

In addition to the resistance method and voltage method for this type of fault, there is a simpler and more feasible method, which is the short circuit method.

The method is to use a well-insulated wire to short-circuit the suspected disconnected part.

If it is short-circuited to a certain place, the circuit operation returns to normal, indicating that the place is disconnected.

The specific operation can be divided into local short connection method and long short connection method.

The above several inspection methods should be used flexibly and abide by the safety operation regulations.

For the components that are continuously burned out, the reasons should be found before replacement;

the voltage drop of the wire should be considered when measuring the voltage; the principle of equipment electrical control should not be violated.

Slightly less than the rated current; pay attention to the selection of the gear of the measuring instrument.