1: The lighting distribution board is not inspected when entering the site.

Consequences: The lighting distribution board has not been inspected after entering the site, and it is often found after installation: its two-layer board does not have a dedicated grounding bolt, the protective ground wire cross-section is small, and the openable door equipped with electrical appliances does not use bare copper flexible wire Reliable connection with the metal frame, the connection between the wire and the appliance is not firm, there is a reverse phenomenon, the screw nut does not need galvanized parts, the wire diameter of the wire does not meet the requirements, it is not marked by color code, there is no card cabinet and electrical wiring diagram, the layout and spacing of the appliance Unreasonable, N and PE terminal blocks are not set. Further modification of the delayed schedule also affects the quality.

Measures: First of all, when processing and ordering, the technical requirements that meet the design and specification standards should be proposed to the manufacturer. The manufacturer is requested to make samples and re-production after passing the acceptance; and when the product enters the site, the inspection and acceptance are strictly in accordance with the design and specification standards. , And then install after confirming qualified.

2: Lighting distribution boards use wood materials that are not flame-retardant.

Consequences: If the lighting distribution board is used in a humid and dusty place, it is easy to mold and leak electricity; in addition, the wooden board is not subject to flame retardant treatment, which is easy to cause fire and is a hidden danger of insecurity.

Measures: To ensure safe use, it is required that the lighting distribution board should not be made of combustible materials. Even if it is in a dry and dust-free place, the wooden distribution board used should be used after flame retardant treatment.

3: The lighting distribution board is not installed firmly, and the elevation does not meet the requirements. When concealed, the edges around the panel are not close to the wall.

Consequences: The elevation of the lighting distribution board installation does not meet the requirements, the installation is not firm, the cabinet is not vertical, and the edges around the panel are not tightly attached to the wall when concealed, which affects the use function and has a bad look.

Measures: The elevation should meet the design requirements. When the design does not specify, the bottom edge of the lighting distribution box should be 1.5m above the ground. The height of the bottom edge of the lighting distribution board should be 1.8m. The lighting distribution board should be installed firmly, and the allowable deviation of the installation verticality should not be greater than 3mm. When concealed, there should be no gaps around the distribution box, the edges of the panel should be close to the wall, and the box should be in contact with buildings and structures. Apply anti-corrosion paint to the parts.

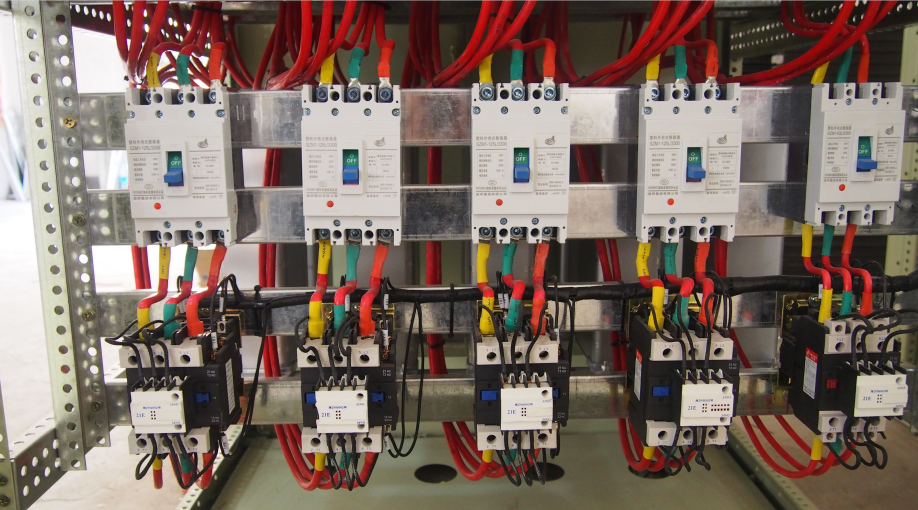

4: The wiring in the lighting distribution board crosses and is messy, not bundled into bundles.

Consequences: The wiring in the lighting distribution board is messy. The two-layer board in the box presses the nozzle tightly, which affects the wire entering the box. If it is forced into the box, the insulation of the wire will be damaged for a long time, and it is easy to cause a short circuit. Inconvenience of overhaul and affect perception.

Measures: When using metal boxes for lighting distribution boxes, anti-rust and anti-corrosion treatment should be done. The outlet hole in the box can not be opened by electric welding. One tube and one hole are needed. The metal box hole must be protected before the threading. The lines should be neatly arranged, the position of the pipe into the box should be reasonably arranged, and the two-layer board should not be pressed tightly on the pipe. The wires in the box should be coiled straight around the box and bundled into a neat bundle.

5: N and PE busbars are not set in the lighting distribution board.

Consequences: N and PE busbars are not installed in the lighting distribution board, and the safe operation of the line cannot be guaranteed.

Measures: In the lighting distribution box (board), busbars of neutral (N) and protective earth (PE) should be set separately. The neutral and protective earth should be connected to the bus, and they should not be twisted and should be There are numbers.

6: The wiring of the spiral fuse installed in the lighting distribution board is not correct.

Consequences: Improper wiring of the spiral fuse installed in the lighting distribution board connects the power cord to the threaded terminal, which affects the replacement of the fuse core, and improper operation may easily cause electric shock.

Measures: To ensure safety, the spiral fuse installed in the lighting distribution board, its power line should be connected to the terminal of the middle contact, and the load line should be connected to the threaded terminal.

7: The protection line of the lighting distribution board cannot be made in place, and the wire diameter does not conform.

Consequences: The protection wires of the lighting distribution board are not arranged from the terminals, but are connected in series using the box frame. The wire diameter is not set according to the requirements. The devices with over-safety voltage on the door of the distribution box are not provided with protective ground wires. It is easy to cause security accidents.

Measures: According to the requirements of the specification, a protective ground bus bar should be installed in the lighting distribution board, and the protective ground wire should be connected on the bus bar. The cross-sectional area of the protective ground wire should not be less than the cross-sectional area from the power supply to the largest lead of the electrical appliance; and it should also be selected according to the relevant regulations. The grounding on the distribution board should be firm and good, and there must be anti-loosening devices. For openable doors equipped with electrical equipment of more than 50V, the movable panel shall be reliably connected to a well-grounded metal frame with bare copper flexible wire. The cross-sectional area of bare copper flexible wire should also be selected in accordance with regulations. The metal box and box body with a wall thickness of less than 2.5mm should not be used as a crimping point for the pipeline’s grounding wire and the protective ground wire of the electrical appliance. The cross-sectional area of the protective ground wire is according to the cross-sectional area of the protective ground wire (mm2). The cross-sectional area of the phase conductor of the device corresponds to the cross-sectional area of the protective conductor SP

S≦16 SP=S

16≦S≦35 SP=16

S>35 SP =S/2

8: The gate of the lighting distribution board is not marked with the name of the circuit.

Consequences: The gates in the lighting distribution board are not marked with the circuit name, which brings inconvenience to use and maintenance. If the gates are not properly closed, it is easy to cause a safety accident.

Measures: Generally according to the requirements of the standard, the wiring system diagram should be posted in the door of the lighting distribution board, and the circuit name should be marked on the gate, especially if there is AC, DC or different in the lighting distribution board Grade power supply should have a clear sign. Bring convenience and safety to the work of users and maintenance personnel.

9: The electrical appliances and instruments in the lighting distribution board are not installed firmly or evenly, and the spacing does not meet the requirements.

Consequences: The electrical appliances and instruments in the lighting distribution box (board) are not installed firmly, flat, and the spacing is not enough, which affects the safety of use.

Measures: The electrical appliances and instruments on the lighting distribution box (board) should be firmly installed, flat and tidy, the spacing should be uniform, the copper terminals should not be loose, the opening and closing are flexible, and the parts are complete.

10: The wires in the lighting distribution board are not threaded according to the color code.

Consequences: If you do not thread according to the color code, when using a single-phase circuit, because it is not easy to identify the three-phase power supply, it is difficult to balance the load, causing a serious three-phase imbalance. When using three-phase equipment, there is no color It is easy to mix the phase sequence when wiring. When some equipment needs fixed steering, it is difficult to grasp the direction of rotation.

Measures: In order to ensure safety and construction convenience, the wires in the lighting distribution board can be penetrated into the pipe according to the regulations, but the main line circuit from the pipe nozzle to the main switch of the distribution board and each use The electrical branch should be separated according to the requirements of the color scale. In this way, when the single-phase circuit is used, its load can be well balanced, and when the three-phase power supply is used, the wiring is in phase sequence to ensure the normal operation of the equipment.

11: The removable metal plate in the lighting distribution board is not connected to the protective earth system.

Consequences: The detachable metal plate in the lighting distribution box is equipped with various electrical accessories, and it is easy to cause an electric shock accident without connecting the protective ground wire.

Measures: The removable metal plate in the lighting distribution box should have reliable grounding protection. Therefore, it is required that the metal plate should be provided with a special non-removable grounding screw, and the protective ground wire should be effectively connected to it. The wire diameter of the protective ground wire should be matched according to the specifications and standards to ensure safe use.

12: Improperly located lighting distribution board in the shaft.

Consequences: The lighting distribution box is set in the shaft, because there are strong and weak currents in the shaft, and the space is very small, which is not easy to operate and a little careless, it is easy to cause safety accidents.

Measures: After receiving the drawings, the drawings should be carefully reviewed. If it is found that the layout of the electrical pipes and cabinets in the shaft does not meet the requirements of the standard, it should be proposed when the design is communicated. It is generally required that no less than o should be left in front of the lighting distribution box and terminal box in the electrical shaft. 8m operation and maintenance distance. In order to prevent the interference of strong electricity to weak electricity, arrange the strong electricity and weak electricity on both sides of the shaft or take isolation measures.

13: The wiring in the floor distribution board is too low.

Consequences: The outlet of the wire and pipe laying in the floor-type distribution box is too low, which can easily cause water and debris to enter the pipe and reduce the insulation strength of the wire.

Measures: The wire protection tube in the floor-mounted distribution box should be 50-80mm above the base of the distribution box. The pipeline should be neatly arranged and the nozzle should be trumpet-shaped.

14: All metal accessories in wiring and electrical installation lighting projects are not galvanized or anti-corrosive.

Consequences: The metal accessories are not galvanized or anti-corrosion treatment, which is easy to corrode and shorten the service life.

Measures: In order to ensure the quality of the project and extend the service life, it is required that the metal accessories used in the wiring and electrical installation lighting projects such as pipe clamps, brackets, hooks, pull rings and box bolts, nuts and other ferrous metal accessories, All should be galvanized or coated with anti-corrosion paint.